Spotlight: Traditional Oil Gilding

Find out more about our traditional oil gilding services and the history of this gold application technique.

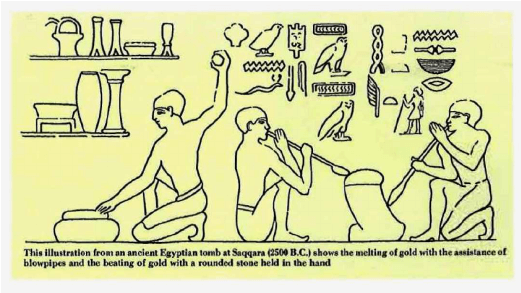

Gold leaf has been used decoratively for thousands of years, having been associated with wealth and beauty in cultures across the world. An illustration from an Egyptian tomb in Saqqara of about 2500 BC shows gold being beaten with a rounded stone, and in the Louvre in Paris, there are some leaves of gold that were found amongst Egyptian remains that are the same size as those used nowadays, albeit slightly thicker.

Some of the oldest known gilt artefacts are silver nails from northern Syria, the heads of which have been wrapped in gold foil. In these examples, the gilding does not rely on a physical or chemical bond between the gold foil and the substrate. Over time however, the skill was further developed in two separate ways: by adding an adhesive between the gold and the base object, and by overlapping layers of gold foil and burnishing them.

To begin with, the thicker gold foil was used for gilding but as the craft developed over time, the gold became thinner and became the ‘gold leaf’ we know and use today.

There are two main types of gilding: water gilding and oil gilding which differ in the way that the gold leaf is applied. Water gilding can be burnished to give high reflectivity whilst oil gilding cannot, whereas oil gilding is water resistant and can be used outdoors which is not the case with water gilding. Out of the two, oil gilding is more straightforward and can be used in a variety of projects and settings.

Gold ‘size’ is a type of glue or adhesive that is based on boiled linseed oil which is applied to a specially prepared surface. The size is then left to dry for a period of time in a dust-free environment, in order to oxidise and develop the appropriate level of tackiness to then allow for the application of the gold leaf.

Application of oil size itself is an extremely important part of the gilding process and can take some time to perfect. At Britain & Co., our gilders spend several months perfecting their sizing before laying any gold leaf to get a feel for the material and the best sheen possible.

Often, the assumption is that gold only comes in one or two shades, popularised by the availability of yellow and white gold in jewellery. In fact, there are several different colours of gold available. We work closely with our suppliers at Gold Leaf Supplies to ensure that we provide the most suitable shade leaf for the project, be it the traditional yellow gold, more of a pink tone as seen in the champagne gold, or the cooler, more muted tones of moon gold.

Whilst oil gilding may be fairly straightforward, this hasn’t prevented the craft from joining the Heritage Craft Association’s Red List of Endangered Crafts as the number of competent professionals able to undertake gilding is in steady decline. Courses in gilding are mainly hobbyist and don’t deal with the craft as it was historically, instead offering modern alternatives and skills are often not passed down within commercial companies and workshops. Britain & Co. tends to buck the trend in this regard, placing a high amount of value in these skills and offering all of our team members the opportunity to learn, thus doing our small part in preventing the extinction of this dying art.

Another factor affecting the prevalence and quality of gilding has been the increase in availability of gold paint. Since it became widely available in the 1980s, gold paint has been applied fairly liberally to a lot of perfectly fine gilded surfaces that needed a professional clean, rather than retouching. This paint can not only damage the gold surface if applied incorrectly, but also oxidises fairly quickly to a greenish-brown so whilst maybe solving a problem in the short-term, has far greater implications for the long-term of the surface.

Britain & Co. are highly experienced with both internal and external gilding and have completed a number of projects applying gold leaf to various different surfaces including cornicing, skirting, ceilings, door panels, memorials and many more. For more information about our gilding surfaces, or to speak to us about a possible gilding project, please contact us on 0207 917 1724 or email us at info@britaindecoration.com.